Sean Delaney: Learning to thread turn

Follow Sean's weekly blog as he completes a three-year advanced manufacturing apprenticeship.

Week ending February 26

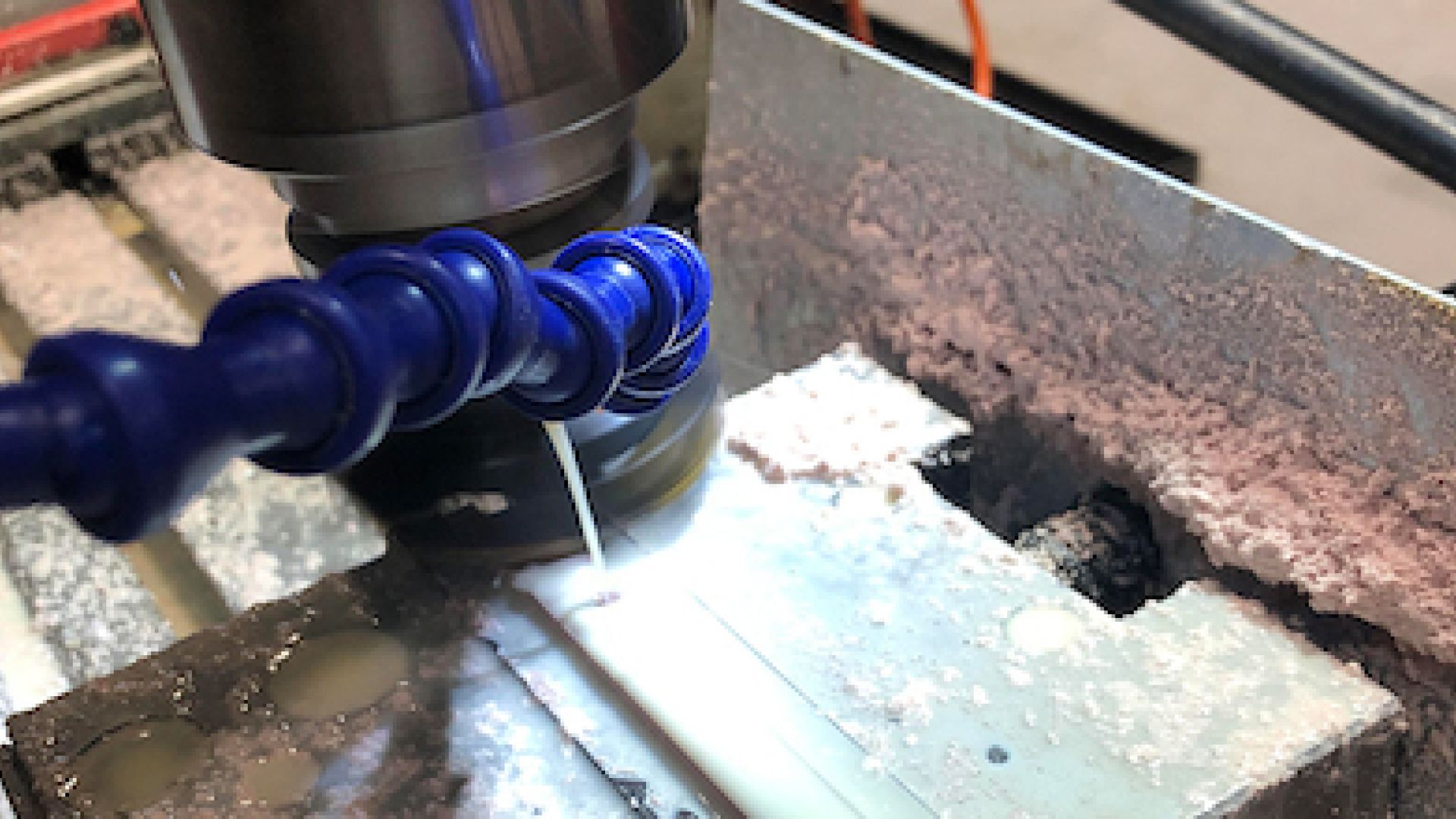

I’ve spent the last week back at work in the AMRC Structural Testing Centre. Whilst there, I was taught to thread turn to further expand upon what I’ve been doing at the AMRC Training Centre. This was an area that wasn’t taught in great detail on the manual lathe. It was different to other types of machining I’ve done in the past in that the given size may not fit perfectly with the nut you are producing the thread for, so it involves bringing the thread down to size until it fits the nut securely. This results in the job taking a significantly larger amount of concentration because the tool had to be removed from the work and the chuck put into reverse just as the tool entered the recess at the back of the thread. The precision needed to avoid crashing the tool was challenging but that just added to the enjoyment of learning the important skill that is thread turning.