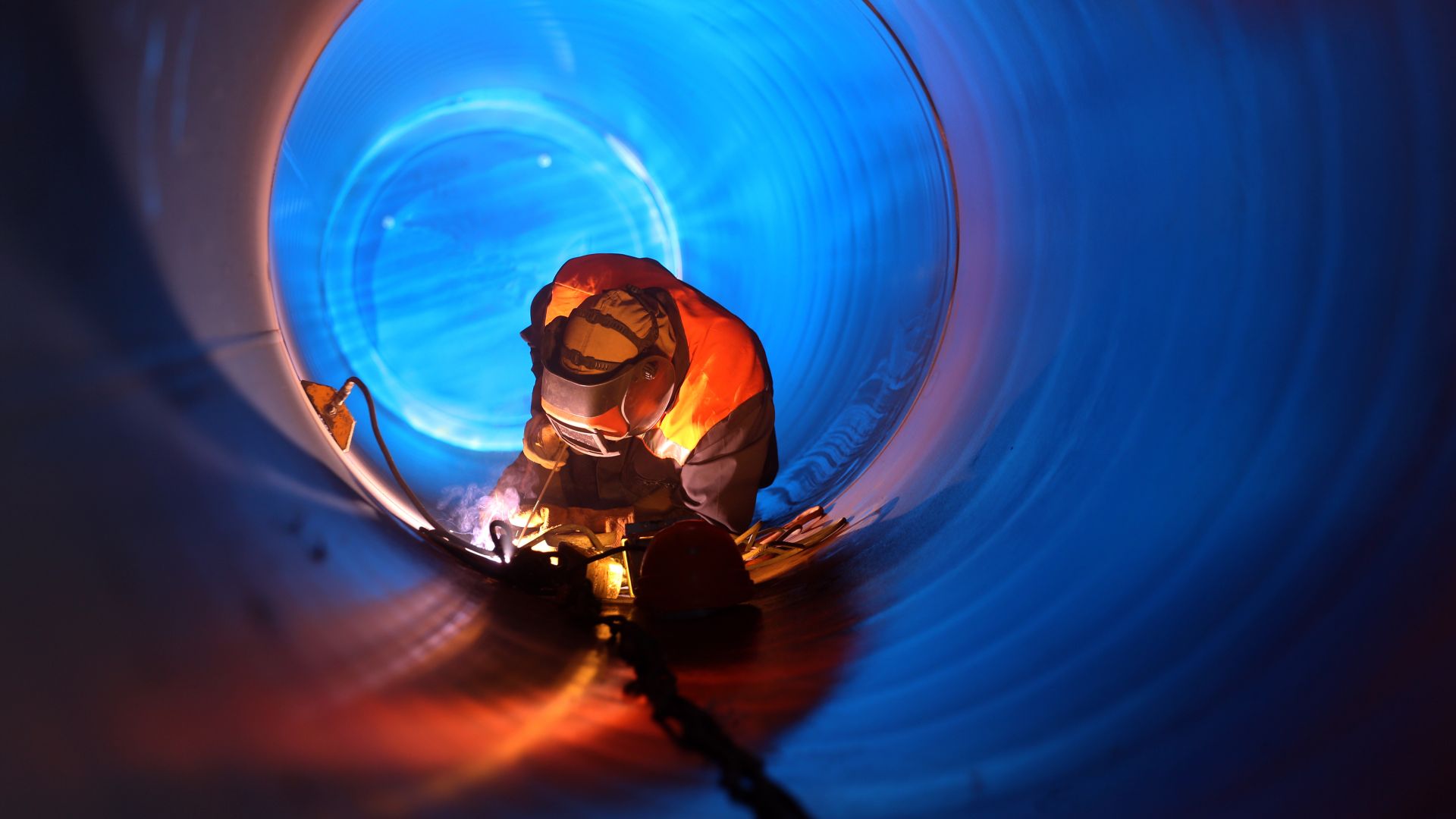

Introduction to TIG Welding

Description

A four-day introduction to the basic concepts of TIG welding, and typical applications in today’s modern engineering environment. This programme enables the candidate to gain an understanding of the principles employed in TIG welding.

The learner will gain an understanding of the aspects of the welding processes used in the manufacturing industry, the basic health and safety requirements in welding, equipment set up and selection, and identification of the main components and their functions. Explanation, demonstration and the practice of TIG welding.

Who should attend?

Anyone who wishes to learn how to start TIG welding and has no prior knowledge. This course is also suitable for employees who are starting to utilise TIG in their workplace. The programme is also flexible enough to be adjusted to meet individual training needs.

Book either Introduction to MMA Welding or Introduction to MIG Welding alongside the Introduction to TIG Welding and receive a discounted price of £1500 (saving £200).

Book both the Introduction to MMA Welding and Introduction to MIG Welding alongside the Introduction to TIG Welding and receive a discounted price of £2250 (saving £300).

To claim the discount, please email cpd@amrctraining.co.uk before booking, with your requirements and to receive further information.

Group bookings:

Claim a discount of £50 per person when booking a group.

To book, get in touch at cpd@amrctraining.co.uk. Please note - A minimum of three people is required for a group booking.

Alternative dates:

If this date is not convenient for your training request, please contact us directly at cpd@amrctraining.co.uk, and we can explore alternative options to accommodate.

Course content - Introduction to TIG Welding

- Health and safety in welding (including first aid requirements)

- Introduction to TIG welding

- Virtual reality welding training (This helps the welder perfect their skills in a challenging virtual environment)

- Torch set up demonstration and practice

- Equipment selection and their applications

- Techniques – manipulation of the welding to three-layer

- Produce a three-layer pad weld

- Tack welding practice

- Gas types, their function and the role

- Gas flow rates

- Consumables used in TIG welding

- Tungsten selection and sharpening

- TIG filler wire manipulation

- Common problems found in TIG welding, explore how they can be identified and how they can be resolved

- Methods of fault finding/detection

- TIG welding terminology and abbreviations

- The applications of various filler materials

- Produce a steel container and complete a lpla test

- Produce various welding test plates’

- e.g. Tee fillet, lap joints, corner joints and butt joints in the horizontal and flat positions